Read How I Got Into The Arts Here:

- Read Part 1 Here: How I Got Into the Arts Part I: College and Jewelry

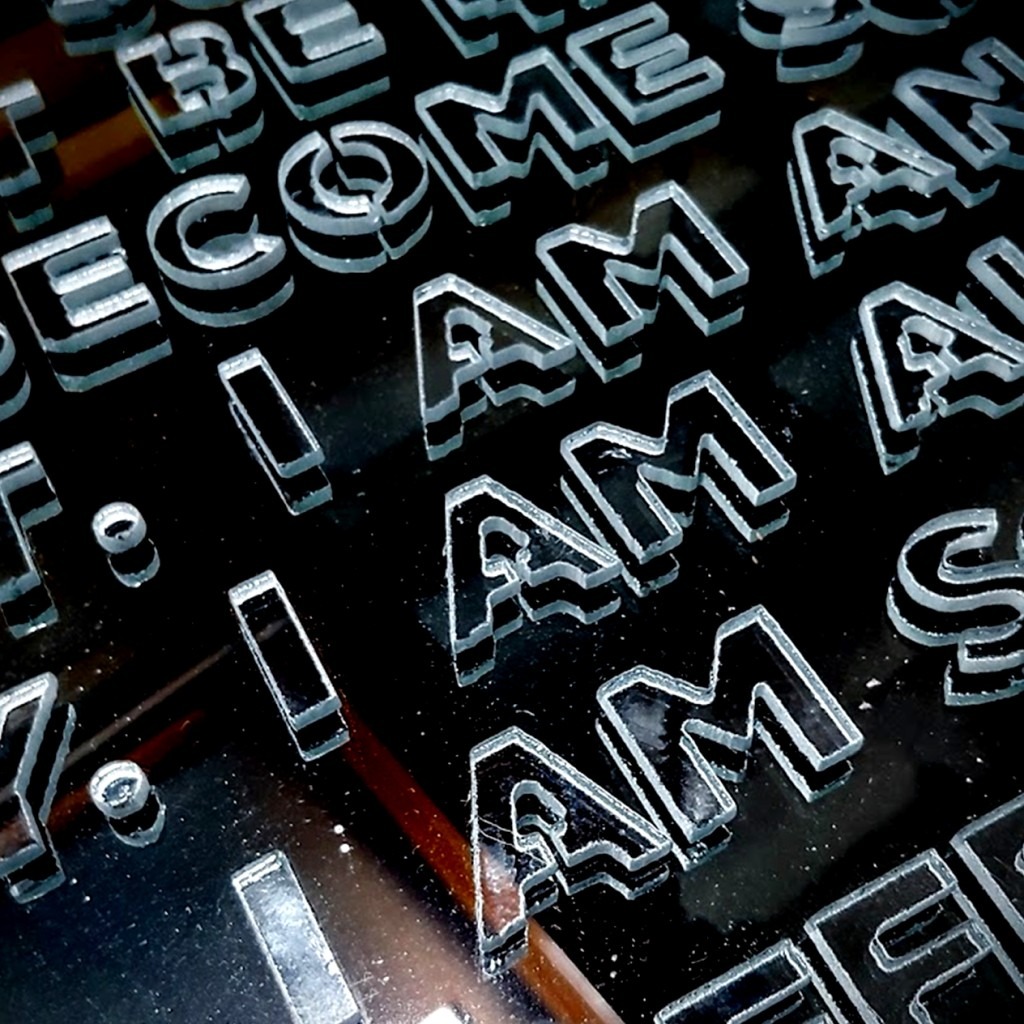

- Read Part 2 Here: How I Got Into the Arts Part II: Cookie Cutters

- Read Part 3 Here: How I Got Into the Arts Part III: Frank and The Artwalk

- Read Part 4 Here: How I Got Into the Arts Part IV: Making a Splash at MGA

- Read Part 5 Here: How I Got Into the Arts Part V: The Police Station

2,500 PSI. That is the amount a pressure washer generates that you’d use to clean concrete. If you aim it in the wrong direction it’ll take your skin right off your foot.

90,000 PSI.

That is the pressure that a waterjet cuts at. The power of 45 pressure washers.

If you’ve never heard of a waterjet machine, you’re not the only one.

A waterjet is an industrial tool capable of cutting a wide variety of materials using an extremely high-pressure jet of water, or a mixture of water and an abrasive substance.

AKA a bad ass piece of equipment that cuts up to 1/1000” accuracy.

It is a bizarre thing to watch, a high pressure stream of water effortlessly cutting through any material you put on it at any thickness. A list of the things I’ve cut on it that come to mind:

You may be wondering why you’ve never heard of this machine before? Well, the answer is that it is a very specialty machine, and there frankly aren’t a lot of them in the world. Most machine shops will use laser or plasma or CNC routers, because they are much CHEAPER to own.

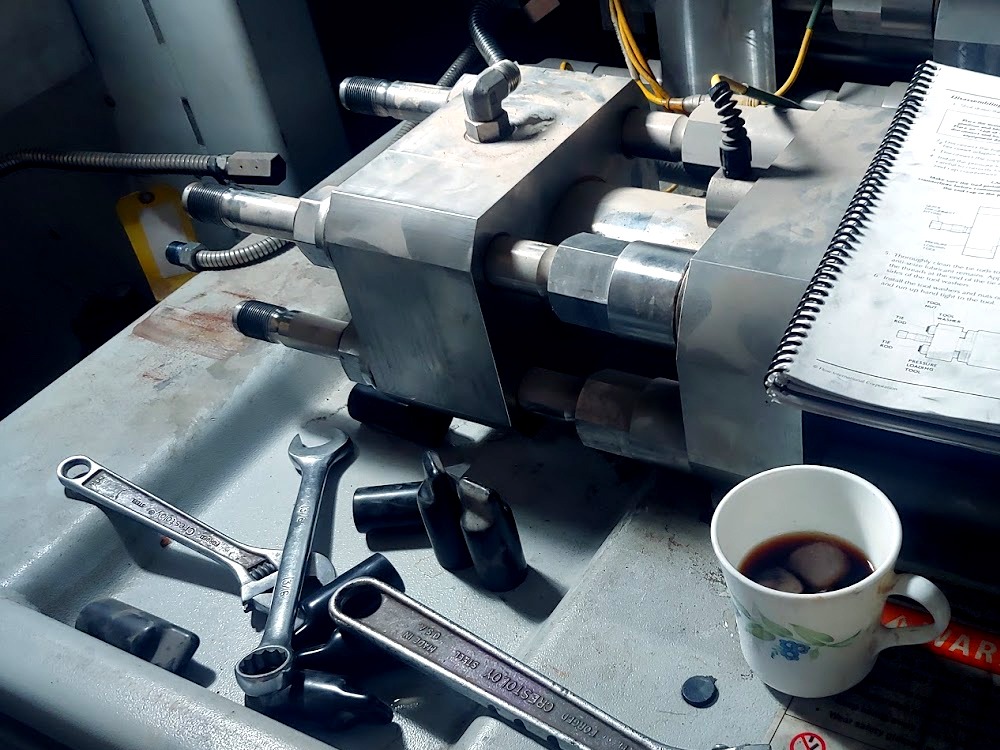

The waterjet really shines in 2 areas: cutting unconventional materials and very thick materials. However, it is much slower than all the other machines on the list, which is why it is not a popular choice in manufacturing. And it is extremely messy and needs quite a bit of maintenance. I can tell you from a 6 hour rebuild on the pump that it is not a machine for the faint of heart.

But what it can cut is amazing. MGA’s sculpture of the First Flight airplane at the St Pete Pier? That’s 16,000lbs of stainless steel cut on a waterjet. In the right hands, it is the only cutting machine you need.

So, why do I like using the waterjet? I have experience with 3D printing, laser cutting, and milling. But the waterjet blows them all away in the amount of materials it can cut and the ease it can cut them with. And I’m generally never in a rush to cut anything. If you don’t have a favorite medium to work in, the waterjet allows you to really pick any material that works for whatever a project calls for.

Stay Tuned for the Next Post: CAD: Computer-Aided Design